Bently Nevada Case Expansion and Valve Position Transducer Systems

GE Bently Nevada offers a very wide variety of vibration, position, speed, pressure and power sensors and transmitters, each designed to handle the rigors of industrial environments and many capable of being installed in hazardous areas when appropriate I.S. barriers, galvanic isolation, or other means are used.

An important position measurement in Turbine Supervisory Instrumentation (TSI) is case expansion. Case expansion (sometimes referred to as shell expansion) is the thermal growth of the machine case as it expands during machine startup and on-line operations. The case expansion transducer system is typically mounted on the foundation at the opposite end from where the turbine casing is attached to the foundation and provides information about the growth of the machine case relative to the foundation.

Features and Benefits

• To determine whether machine conditions are exceeding expected

temperature growth differentials.

• To determines whether the machine casing and rotor grow thermally at

nearly the same rate.

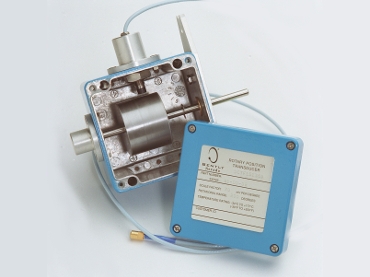

The 3300 XL Rotary Position Transducer (RPT) measures angular

rotation. Its most common use is for measuring valve position on steam

turbines allowing for:

• Utilizing valve position information to adjust inlet valves,

• Determining operating efficiency and measuring the load of the turbine.

The 18639 Valve Position Transducer measures the opening of governor valves on the steam turbine so you can

• Monitor and adjust the amount of steam that flows to the individual

valves in the group to provide the highest machine operating efficiency.

The 3300 XL Rotary Position Transducer (RPT) measures angular rotation. Its most common use is for measuring valve position on steam turbines. Valve position information is utilized to adjust inlet valves, determine operating efficiency and measure the load of the turbine.

The 3300 XL RPT attaches to the end of a steam valve control shaft using a flexible coupling (not provided). The 3300 XL Rotary Position Transducer consists of a housing, cylinder and shaft, conduit fitting and a non-contacting eddy-current 3300 XL Proximity Transducer System. The 3300 XL probe views the precisely machined cylinder. As the steam turbine control valve opens or closes, the steam valve control shaft and the 3300 XL RPT cylinder rotate. This causes the gap voltage reading of the Proximity Transducer System to change. The change in the gap voltage is proportional to the change in valve opening. The 3300 XL RPT is available in three different rotational ranges to optimize its performance - 100 degrees, 200 degrees, or 300 degrees. It is compatible with our 3500/45 Position Monitors. The 3500/45 monitor and 3300 XL RPT utilize the advanced "Transducer OK" checking inherent in Bently Nevada eddy current proximity transducer measurements.

Bently Nevada Case Expansion and Valve Position Transducer Systems

Bently Nevada CASE EXPANSION AND VALVE POSITION TRANSDUCER

BENTLY NEVADA SCOUT

Model

Requires -17.5 Vdc to -26 Vdcwithout barriers at 12 mA maximum consumption.

Power

<

>

Less than 2 mV change in output

voltage per volt change in input

voltage.

Supply Sensitivity:

50Ω

Output resistance

140 + 8 mV/degrees of shaft rotation.

Average Scale Factor

100° Ramp:

70 ± 4 mV/degrees of shaft rotation.

Average Scale Factor

200° Ramp:

50 ± 3 mV/degrees of shaft rotation.

Average Scale Factor

300° Ramp:

69.9 pF/m (21.3 pF/ft) typical

Extension cable capacitance

0.2 to 1.5 mm2 (16 to 24 AWG) [0.25 to 0.75 mm2 (18 to 23 AWG) with ferrules]. Recommend using

three-conductor shielded triad cable. Maximum length of 305

Field wiring

10 cm to 2 m nominal

Laser sensor range

Product Info

Documentation

Case Studies

Training & Support

Video

How does it work?

The 3300 XL Rotary Position Transducer (RPT) measures angular rotation. Its most common use is for measuring valve position on steam turbines. Valve position information is utilized to adjust inlet valves, determine operating efficiency and measure the load of the turbine.

What problems does it solve?

Title

Description

Actions

Title

Description

Actions

No data available in table

Title

Description

Actions

Previous

Next

Head office

1 Adeola Odeku Street

South Atlantic Petroleum Towers

Victoria Island | Lagos | Nigeria

Tel: +234 1904 9589, +234 (0) 909 026 0055

Lagos Branch Office

15, Ogundana Street | Off Allen Avenue |

Ikeja | Lagos | Nigeria

Stay Connected With Us!

GCA Energy Staff Email

Access Email Service

Port Harcourt Branch Office

15 Emeyal Street

GRA Phase I

Port Harcourt, Rivers State, Nigeria

Tel: +234 8093906260